FEA & CFD computer modeling

Over the years our engineers have designed specialized equipment for a variety of industries. There was usually one factor common to all. Whether the application was semiconductor, solar, medical device, vacuum coatings, or any of a multitude of others, each had a single critical component or subsystem that is the heart of the system and if it doesn't perform as expected then neither does the system as a whole.

MAPEK

Engineering LLC

Practical experience combined with state of the art computer modeling using finite element analysis (FEA) or computational fluid dynamics (CFD) can boost your confidence in a design to a much higher level. Knowing in advance how much coolant will flow through a heat exchanger or knowing whether your heater platen temperature will be uniform before you build them can save you time, expense, and needless revisions.

We offer our clients several levels of service to suit their needs. At the basic level, we can model your existing structural, thermal, or flow design and confirm its performance. If you are developing a new system, we can work with you on a design project and perform iterative modeling so you can optimize your design and/or materials. Utilizing our extensive in-house design experience, we can also design from scratch and optimize components and systems for our clients based on their specifications.

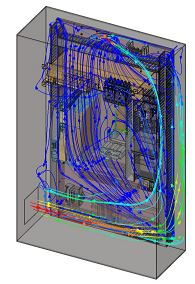

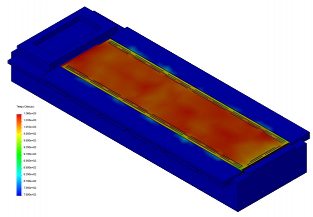

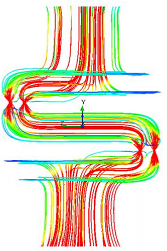

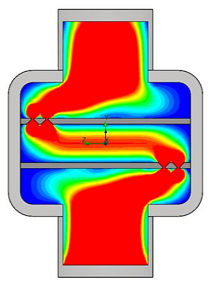

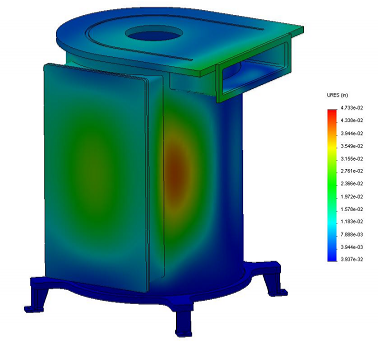

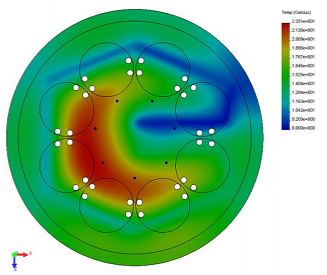

Practical engineering experience is essential whether you are designing the gas orifices for a laminar flow furnace, the platen for a high uniformity substrate heater, the exhaust system for a gas cabinet, or the cooling circuit for a heated component.

At Mapek Engineering, we utilize the outstanding suite of simulation software from SolidWorks running on our high performance computers to model our clients' applications.

Whatever your needs, consider Mapek Engineering for your next design verification.

Contact us and see what we can do for you!

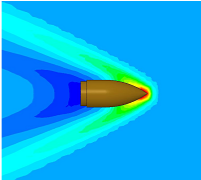

Projectile Pressure Waves

Gas Trajectories & V Profile in a Laminar Flow Furnace

T Profile of an 800 C Platen; I.R. Heated & Water Cooled

Vacuum Chamber Deflection

T Profile of a 1M Diameter Water Cooled Wafer Deposition Dial

Air Flow in a PD Cabinet